Cavalok

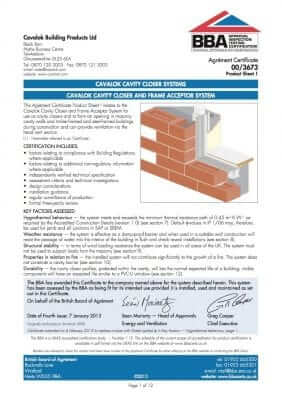

Eurocell is the UK’s number one manufacturer, distributor and recycler of uPVC. Since 1974, they have been committed to developing products that meet the changing needs of architects and specifiers as well as fabricators and installers. It is their window, door, conservatory and roofline products that have established them as the nation’s number one but their acquisition of Merritt Plastics recycling and Cavalok have entrenched them as a market leader in innovative, sustainable products.

Boasting precision extrusion, excellent customer service and continued product innovation, energy efficiency, sustainability and aesthetics are integral to Eurocell’s development and unique range of products. As a result, Cavalok cavity closers have become an essential building component for commercial and residential projects alike and are widely used across the UK.

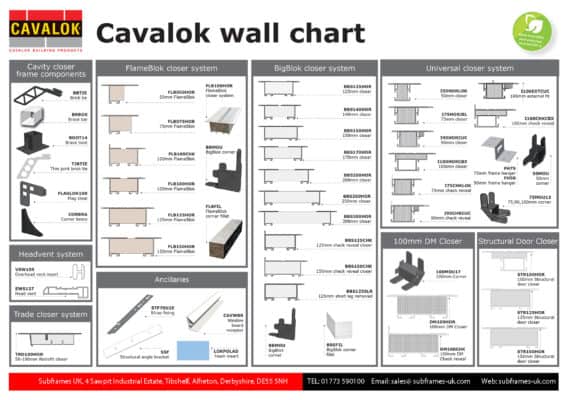

Made from 100% recycled materials, Cavalok cavity closers are the market-leading cavity closer system. One of the simplest yet most effective ways of sealing cavities around wall openings, they provide a rigid template ideal for bricklaying as well as window and/or door installation. Perhaps most pertinent, Cavalok’s innovative product range makes them suitable for all new build applications and allows specifiers to meet current legislation demands as well as be prepared for any future changes.

For quotations, product information or technical support please call us on 01773 590100 or email sales@subframes-uk.com

FAQs

Are Cavalok cavity closers energy efficient?

Through Eurocell, Cavalok offers a range of energy-efficient cavity closers ideal for sealing your home against the elements. For example, BigBlok, one of the primary products supplied by Cavalok, is a leading insulated cavity closer system designed for larger cavity widths and low-carbon buildings.

For more information about energy-efficient cavity closers, please call the team at Subframes UK today on 01773 590100 or email [email protected]. You can also contact us via our website.

Will Cavalok cavity closers work with a timber frame?

The Cavalok cavity closer system can be used with timber framing as well as other frame construction types by utilising their unique frame hanger system. This system is designed to support the closer before the construction of the external skin through the internal frame.

What are the benefits of Cavalok cavity closers?

Cavalok cavity closers are engineered from 100% recycled uPVC and are environmentally sustainable. By utilising post-consumer waste that would ordinarily end up in landfill, Cavalok presents an environmentally sustainable choice for an exceptional energy-efficient system, other benefits of Cavalok cavity closers include:

- A polystyrene core for enhanced thermal efficiency and Part L compliance

- Compatible with most uPVC window systems, as well as timber and aluminium

- Future Homes Standard compliant and Part L 2021 & 2025 ready

What is a cavity closer used for?

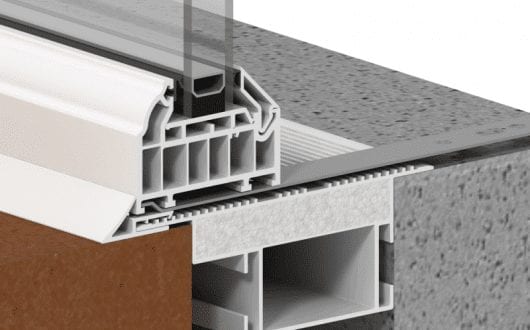

In a nutshell, a cavity closer acts as a seal. It protects a building from water, damp and condensation from entering the cavity wall. Cavity closers also prevent heat from being lost through any gaps, meaning they can improve the overall energy efficiency and thermal retention ratings of residential and commercial properties alike.

Cavity closers are used to:

- Prevent damp and condensation from entering a building

- Reduce loss of heat and improve energy efficiency, prevention of cold bridging

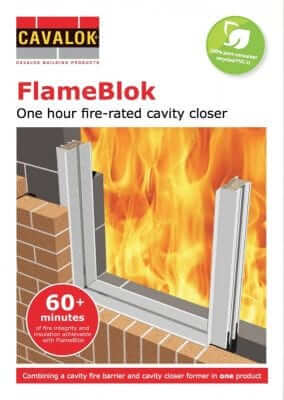

- Improve fire safety, using our FlameBlok fire rated option

Cavity closers can be used in a number of different construction projects. Common projects that utilise cavity closers include the use of masonry, timber frames and steel frame systems.

Do you need cavity closers?

Cavity closers are an essential component in any modern building’s construction. Ideal for improving energy efficiency and thermal retention ratings, cavity closers seal a building by preventing the ingress of water, damp and condensation through the cavity wall. Depending on the type of cavity closer you use, they can also improve the fire safety of a building.

What are cavity closers made from?

The material your cavity closer is made from will depend on the type of closer you choose, as well as the unique specifications of the building and cavity walls. Most modern cavity closers are engineered from uPVC with a durable, fully-insulated core for heightened energy efficiency and thermal retention.

Are cavity closers necessary?

Cavity closers play an essential role in the construction of modern buildings. Acting as an insulating seal, they prevent any external water from entering a cavity wall. As a result, cavity closers can increase the energy efficiency rating of your building, by providing a barrier which effectively prevents heat loss while also stopping any damp or condensation from entering. Furthermore, the FlameBlok, fire rated variants, can also improve the fire safety of domestic and commercial properties alike.

What is the purpose of cavity closers?

The primary purpose of a cavity closer is to provide insulation and improve fire safety. Ideal for installation in both commercial and residential properties, cavity closers act as an insulating barrier and play an instrumental role in preventing heat loss. By keeping external damp and condensation out and keeping any heat in, your property will benefit from warmer, drier, more comfortable internal spaces and heightened energy efficiency.

What are the best cavity closers?

If you’re looking for the best cavity closers, you’ve certainly come to the right place! Subframes UK is the largest supplier of welded and mechanically joined cavity closers here in Great Britain. We manufacture and supply a range of bespoke cavity closers ideal for a number of different construction projects for all types of windows and doors.

From our cutting edge 30,000sqft factory, our professional team engineers 2, 3 or 4-sided frames supplied with or without vented heads, as circles, arches, ovals, mosques or as a combination of T or P-shaped flags. We also offer standard, fire-rated and structural frames from 50mm to 300mm, all of which are manufactured to the highest possible standard.

Subframes UK delivers nationwide from our base in Derby. For no-obligation quotations, product information or technical support from our team, please call us today on 01773 590100 or email [email protected]. You can also get in touch via our website.