Cavity Closers

What are cavity closers and how do you install them?

If you’re in the process of a construction or renovation project or are in the throes of building a new home, you may have come across the term cavity closer. From preventing mould and condensation to creating a fire barrier, cavity closers are a crucial component of your property’s construction.

Here at Subframes, our professional team have years of combined product knowledge and industry experience when it comes to cavity closers. We can give you the advice and guidance you need to complete your insulation project to the highest standard.

But first, what is a cavity closer and do you install them?

What is a cavity closer?

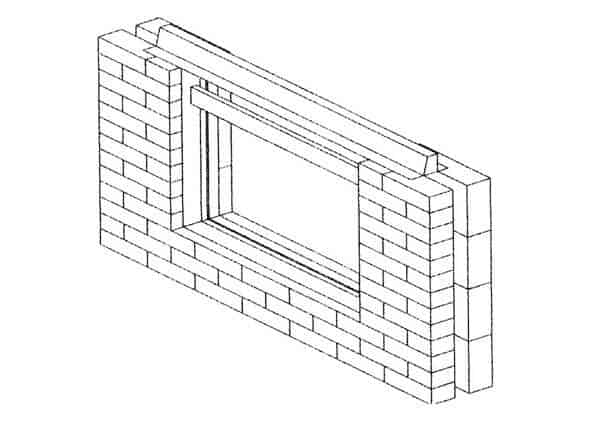

A cavity closer is installed around window and door openings within cavity walls, which usually consist of two layers of brick or block separated by a gap. Its primary role is to effectively seal these openings, preventing external water vapour and dampness from entering the building while also reducing heat loss through the cavity. Cavity closers are versatile and can be used in a range of construction methods, including masonry, timber frame and steel frame systems.

When windows and doors are installed, a cavity closer should be fitted within the cavity wall. Buildings require cavity closers for a variety of reasons, such as guarding against moisture, damp and condensation, as well as preventing the loss of heat. As a result, the cavity closers within your home help to maintain heightened levels of energy efficiency and keep your property dry and comfortable throughout the year.

A cavity closer also assists in improving a building’s fire safety, especially if it is a fire-rated cavity closer. Depending on the product you select, fire-rated cavity closers can stop the spread of fire for 30 minutes to an hour. Fire-rated cavity closers also guarantee your property complies with local fire-safety regulations.

Why Do You Need a Cavity Closer?

The area around windows or doors is particularly vulnerable to water ingress, both from direct rain exposure and any moisture that enters the cavity between walls. Cavity closers act as an effective damp-proof barrier, sealing gaps around window or door frames and redirecting water away from the building.

This protection significantly reduces the risk of dampness, condensation, and mold formation, promoting a healthier and more comfortable indoor environment.

Compliance with Building Regulations Part C: Ensuring resistance to contaminants and moisture is crucial for maintaining building integrity and occupant comfort.

Reduce Heat Loss

Thermal bridging occurs when there is a break in the insulation layer, leading to heat loss and potential cold spots. Well-installed cavity closers create an airtight and continuous insulation barrier around window and door frames. This significantly enhances the overall energy efficiency of the building, reducing the reliance on heating and cooling systems.

Compliance with Building Regulations Part L: Emphasising sustainable practices and energy conservation, Part L promotes efficient building design and operation.

Improve Fire Safety

In the event of a fire, the rapid spread of flames and smoke within a building can be devastating.

Fire-rated cavity closers are specially designed to contain fire at openings like doors and windows, acting as barriers to restrict the spread of flames through these vulnerable points in a building’s structure. Depending on their rating, fire-rated cavity closers can stop the spread of fire for up to an hour.

Compliance with Building Regulations Part B: Focusing on maintaining rigorous fire safety standards within buildings.

How are cavity closers installed?

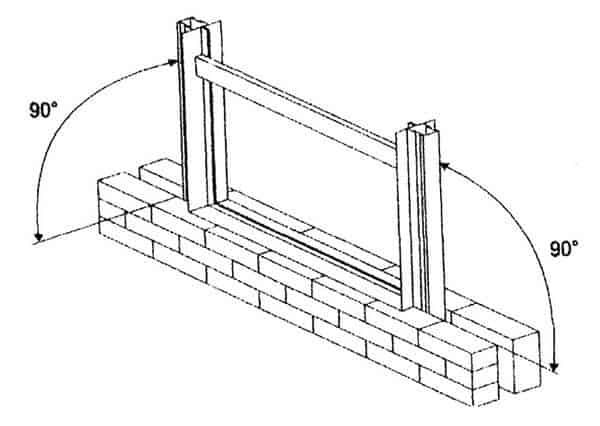

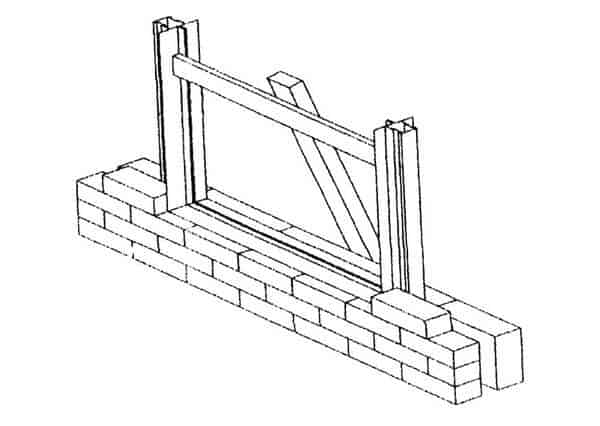

Cavity closers can be installed either before a wall is constructed (first fix) or after the wall is built (second fix).

While first fix installations may be required in specific construction sequences or methods, second fix installations are favoured for their ability to achieve a more precise fit. This approach ensures optimal performance of cavity closers in building envelopes, contributing to better insulation and moisture management.

- Measure and Prepare:

Measure the width of the cavity wall to select the appropriate size of cavity closer. Cut the cavity closer to the correct length, leaving a small gap of approximately 10mm to allow for potential movement or settling. - Positioning:

Place the cavity closer horizontally across the cavity opening, ensuring it fits snugly against both the inner and outer walls. Use spacers or wedges as necessary to temporarily hold it in position.

- Fixing:

Secure the cavity closer by fastening it to the inner and outer walls using suitable fixings such as screws or wall plugs. Ensure the fixings penetrate both the closer and the wall material sufficiently to provide stability.

- Sealing:

Apply appropriate sealant to seal any gaps or joints around the cavity closer. This helps prevent water ingress, drafts or pests from entering. Pay close attention to the junctions between the cavity closer and the walls to maintain the integrity of insulation.

- Check and Finish:

Inspect the installed cavity closer to ensure it is securely fixed and properly sealed. Trim any excess material if necessary and check for any remaining gaps or areas that require additional sealing to ensure optimal performance.

Note: The installation process may vary slightly depending on the manufacturer. For specific instructions, refer to the cavity closer installation guide included with your product. At Subframes UK, we provide a comprehensive installation guide complete with clear instructions and helpful videos for easy installation.

Types of cavity closer

Here at Subframes, we only supply cavity closer systems from a selection of the best cavity closer manufacturers and brands.

Eurocell

Eurocell is the UK’s number one for uPVC. They are a leading manufacturer, distributor and recycler due to their precision extrusion, excellent customer service and continued product innovation.

Since 1974, Eurocell has been at the forefront of developing solutions that cater to the diverse needs of architects, specifiers, fabricators and installers. Their extensive range of window, door, conservatory and roofline products not only prioritises energy efficiency and sustainability but also enhances the aesthetic appeal of buildings nationwide. Eurocell’s commitment to sustainability is underscored by their acquisition of Merritt Plastics recycling and Cavalok, positioning them as pioneers in the recycling and sustainable product sectors.

Cavalok cavity closers are designed to streamline the installation of window and door openings while effectively sealing cavities ranging from 50 mm to 300 mm wide. These closers enhance thermal efficiency, complying with current Building Regulations by integrating built-in insulation. Manufactured from recycled PVC-U, Cavalok closers are not only durable and robust but also quick to fabricate and install, reducing both time and costs on site.

Cavalok offers a range of cavity closers tailored for various applications, including standard window closers, specialist entrance door closers, FlameBlok fire-rated closers and trade closers for refurbishment projects. Each variant addresses specific construction needs, ensuring optimal performance and energy efficiency across different building scenarios.

Dacatie Building Solutions

Dacatie Building Solutions is the manufacturer and supplier of the original range of Insulated Cavity Closers for the UK construction market. As a market leader, Dacatie offers a range of products that ensure compliance with essential Building Regulations, particularly in the construction of cavity walls around windows and doors.

The brand is trusted by specifiers and building contractors alike for its commitment to quality and adherence to regulatory standards. Dacatie’s insulated and fire-rated cavity closers cater to diverse construction needs, ranging from the economical Supafix Closer to the high-performance XFR200 Cavity Closer, which is favoured by architects for its mineral wool fire rating.

Kingspan

Founded in 1965, Kingspan has grown to become a global leader in high-performance insulation and building envelope solutions. With a rich history of over five decades, Kingspan is renowned for its commitment to innovation, sustainability and quality in the construction industry.

Kingspan Kooltherm® Cavity Closer is a uPVC extrusion featuring a rigid thermoset insulation core. Manufactured with a blowing agent that has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP), it meets stringent environmental standards.

Available in thirteen sizes ranging from 50–150 mm, the product includes jointing clips that extend compatibility to cavity widths up to 300 mm. This flexibility makes it suitable for use with timber, metal or uPVC window frames, and it can be customised to order in curved sections.

This is only available as a bar length product.

Timloc

Timloc Building Products has been serving the building industry for over 50 years. Part of the Alumasc Group Plc, the brand is based at their 90,000 sq. ft. manufacturing facility in Howden, East Yorkshire.

Timloc is dedicated to sustainable manufacturing practices, with 75% of their products made from recycled plastics. This commitment aligns with their goal of reducing environmental impact while providing durable building solutions.

Timloc’s cavity closers are available in a variety of specifications, accommodating a wide range of cavity widths and construction needs, ensuring they are versatile and compatible with different building designs.

The Thermo-loc series, in particular, offers a comprehensive range of options, from standard insulation thicknesses to advanced fire-rated solutions. This series is a dependable choice for creating thermally efficient and regulatory-compliant building envelopes.

Titon Vents

Titon is a leading UK manufacturer known for its high-quality ventilation systems and hardware for windows and doors. Their products are designed to ensure proper airflow and ventilation while maintaining the thermal efficiency of the building envelope. By integrating Titon vents with cavity closers, you can achieve a balanced and energy-efficient ventilation system, enhancing the overall performance of your building.

Titon’s Trimvent® Select Xtra S13 and XS16 vents are renowned for their superior ventilation performance and compliance with the latest building regulations. These vents are semi-recessed, clip-fix plastic slot ventilators designed for an 18 mm slot in a window overhead section (vented head). They provide an Equivalent Area (EA) of 4600 mm² (XS16) or 4400 mm² (XS13) when fitted with a pair of GS18 grilles.

At Subframes UK, we can incorporate these vents into any profile (fitted on the opening side) or supply them separately.

Custom Cavity Closer

At Subframes UK, we offer a wide range of cavity closer profiles from leading UK manufacturers, tailored to meet the specific requirements of your property. Our custom options ensure a perfect fit for any structure.

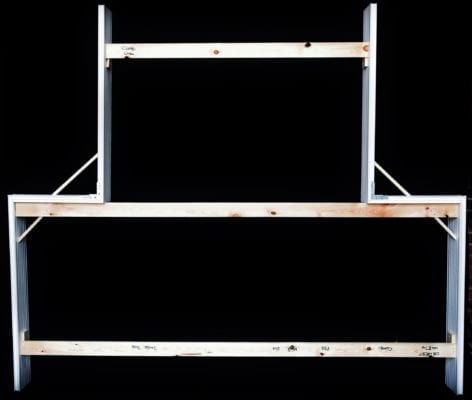

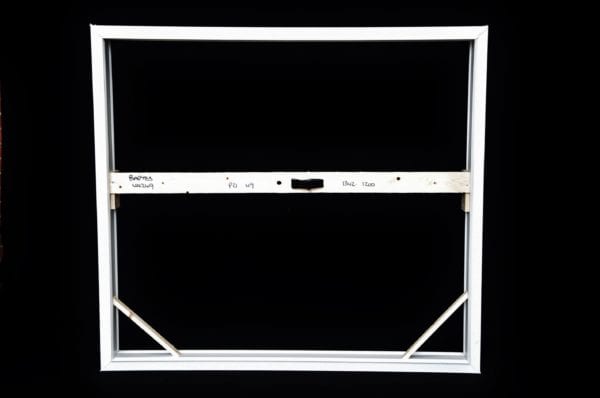

Structural Door Packs

Our structural door packs are designed for the secure and efficient installation of entrance, French, patio and bi-fold doors. These packs include Cavalok cavity closers with structural foam inserts, available in 100 mm, BigBlok 125 mm and 150 mm sizes. The design allows direct fixing through the outer door frame into the cavity closer, eliminating the need for strap fixings and preventing any movement post-installation. Thermally efficient and acting as a damp-proof course (DPC), these door packs ensure superior performance.

Each pack contains two structural door set lengths, one standard non-structural cavity closer and twenty brick ties, providing everything needed for a secure and reliable door installation.

Cavity closers at Subframes

If it’s making sure your house is well insulated or adding a layer of protection from water or fire damage, Subframes UK’s cavity closers are the perfect solution.

Subframes Ltd is the United Kingdom’s leading manufacturer of cavity closer systems. Our uPVC cavity closers are perfectly insulated and are designed to fill any cavity around your windows and doors.

For quotations, product information or technical support, please contact our team today.

For quotations, product information or technical support please call us on 01773 590100 or email sales@subframes-uk.com.

Further Information

Cavity closers for all frames

Subframes UK manufactures cavity closers to suit all makes and types of doors and windows suitable for brick and block, timber frame, Metsec or any other build type.

We offer a bespoke service designed to meet unique specifications from architect design to site approval with samples supplied.

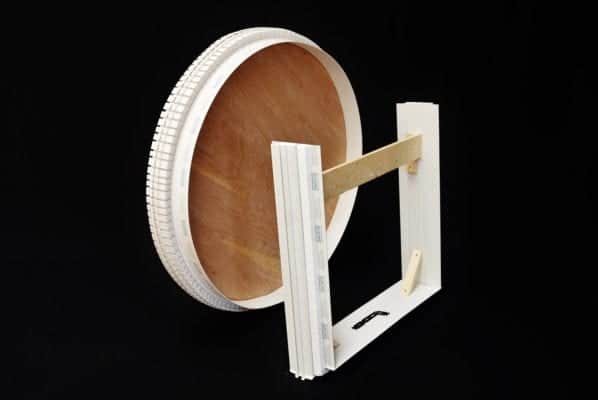

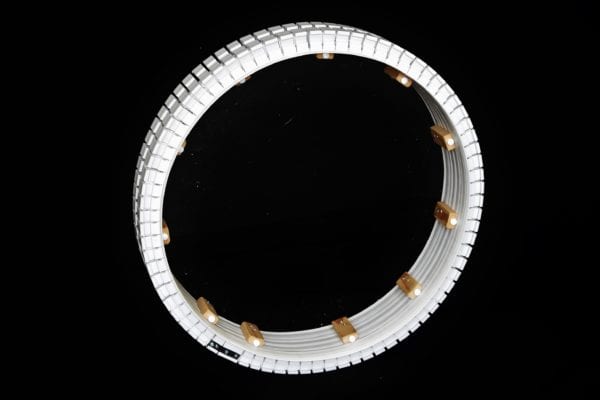

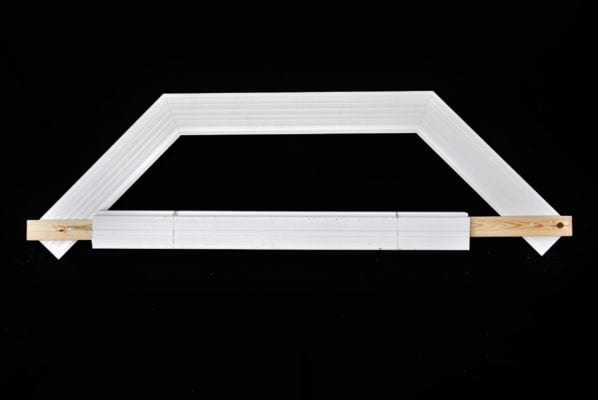

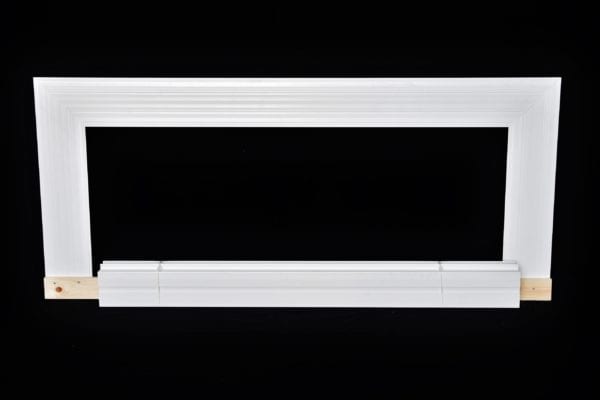

Our cavity closers can be manufactured as 2, 3 or 4-sided frames supplied with or without vented heads, as circles, arches, ovals, mosques or as a combination of T or P-shaped flags.

Supplying Cavity Closers to Manufacturers

At Subframes UK, we supply cavity closers for all parts of the industry, including window and door manufacturers. For this reason, we use a fleet of unmarked vehicles which deliver nationally on a daily basis.

High-quality Cavity Closers

We are the UK’s leading manufacturer of cavity closers. Our uPVC cavity closers are insulated perfectly and designed to fit between any cavity around your windows, doors and walls.

At Subframes UK, we supply the highest quality cavity closers from a number of brands to provide a solution to every type of window and door insulation.

An experienced team

We only supply cavity closers. Our team of industry experts are experienced in cavity closers and is on hand to help with any quotations, product information or technical support you may need when purchasing your cavity closers.

If you are interested in bespoke designed cavity closers, please speak to a member of the team who can arrange this for you. We offer a choice of cavity closer profiles from the majority of the UK’s major suppliers. We can also modify most profiles to facilitate fitting into almost any structure.

When placing your order please ensure that you provide the following information:

- Circular Frames – The diameter size.

- Combination Frames & Stand Frames – A simple sketch with dimensions.

- Arches – A simple sketch with dimensions & spring point.

Supplying Cavity Closers

We supply cavity closers to window and door manufacturers from our base in the East Midlands. For this reason, our cavity closers are delivered daily by our fleet of unmarked vehicles. To order cavity closers from Subframes UK, please get in contact with us via our telephone number or contact form. If you are ready to buy your cavity closers and you know what you would like to order, please see our online order form and our team will endeavour to get back to you within 24 hours; however, if it requires a take-off from drawings, this may take longer.

FAQs

What is a cavity closer?

A cavity closer fits the gap within a cavity wall, where windows and doors are fitted. The cavity closer acts as a seal to prevent water vapour and damp from entering the cavity wall. This prevents damp problems as well as stops heat from being lost through the gap.

Cavity closers are made from a number of different materials. At Subframes we manufacture our uPVC cavity closers using a range of products from manufacturers such as Cavalok, Dacatie, Timloc and more.

There are many types of cavity closers, and we offer a range of cavity closers from a number of manufacturers to suit most builds. However, if you need a bespoke cavity closer, we can manufacture these from your architect’s designs.

Why do you need a cavity closer?

A cavity closer acts as a seal by preventing external water vapour and damp from entering the cavity wall. Cavity closers also prevent heat from being lost through this gap. Cavity closers can be used in a range of different constructions, including masonry, timber frame and steel frame systems.

For window and door installations, cavity closers are essential. Most window and door manufacturers rely on cavity closers from a specialist cavity closer company such as Subframes UK. As a leading market supplier, we offer a wealth of knowledge about cavity closers so that our customers can make informed decisions to support their state-of-the-art products.

How to install Cavity Closers?

Cavity closers can be fitted either before or after the brick wall has been built. If fitted before, it is known as the ‘first fix’. If cavity closers are fitted after the brick wall has been built, it is known as the ‘second fix’.

The installation process may vary depending on the manufacturer. At Subframes we offer a handy installation guide with instructions and video for simple installation.

Is Subframes UK registered by any independent bodies?

We are a registered ISO 9001-2000 company and members of the chamber of commerce. All standard (non-fire) profiles have current BBA certificates and are manufactured to the highest standard in our Tibshelf factory. We produce our cavity closers to UK fire regulations.

It is important to note that cavity closers are not measured by U Value ratings. The calculation required to meet part L of building regulations is the path of thermal resistance. The cavity closer forms part of this calculation. Our cavity closers meet this requirement.

What size are the cavity closers products that Subframes supply?

Subframes UK offers a versatile selection of cavity closers tailored to meet diverse building needs. Our profiles are available in 6 m lengths or can be custom-cut as required. All standard (non-fire rated) profiles are BBA certified and compliant with Part L of the Building Regulations. We source our profiles from leading extrusion houses across the country to ensure quality and reliability.

Our cavity closers are designed to fit all types of doors and windows, suitable for various construction methods including brick and block, timber frame, Metsec and others. We provide a bespoke service that caters to specific architectural designs, offering samples and facilitating site approvals.

At Subframes UK, our range includes 2, 3 or 4-sided frames that can be supplied with or without vented heads. We offer configurations such as circles, arches, ovals, mosques and combinations of T or P-shaped flags to suit unique project requirements.

Our solutions accommodate cavities ranging from 50 mm to 300 mm, with potential options available outside of this range upon special request. For more details or to discuss your project needs, please contact our team for personalised assistance.

Where do cavity closers go?

Typically, a cavity closer fits within a cavity wall, between the outer brickwork and inner blockwork where windows and doors are to be fitted. The cavity closer gives a solid framework that the bricklayer can build up quickly and easily to form the structural opening required for windows and doors.

Can you use Celotex as a Cavity Closer?

No, you shouldn’t use Celotex as a cavity closer. Celotex insulation boards are primarily composed of polyisocyanurate foam, designed specifically for thermal insulation within building elements like walls, floors and roofs. This composition does not provide the structural support or durability required for effective sealing around window and door openings in masonry walls.

Using Celotex instead of cavity closers could compromise the building’s thermal efficiency, structural integrity and compliance with building regulations.

It’s essential to use purpose-built cavity closers made from materials like uPVC to ensure proper performance and longevity of the building envelope.

Is Subframes UK Registered by any Independent Bodies?

Yes, Subframes UK is a registered ISO 9001-2000 company and proud members of the Chamber of Commerce. Our standard (non-fire) profiles hold current BBA certificates, ensuring they meet rigorous quality standards. All products are manufactured to the highest standards at our Tibshelf factory, and our cavity closers comply with UK fire regulations.

It’s important to note that cavity closers are not evaluated by U Value ratings but rather by their contribution to the path of thermal resistance required to meet Part L of the Building Regulations. Our cavity closers are meticulously designed to fulfil this requirement, ensuring optimal thermal performance and compliance.

Do Cavity Closers Require Maintenance After Installation?

Once installed properly, cavity closers typically require minimal maintenance. It’s important to periodically inspect them to ensure they remain intact and properly sealed. Any damaged or compromised cavity closers should be repaired or replaced promptly to maintain their effectiveness in sealing gaps and preventing moisture ingress.

Are Fire-Rated Cavity Closers Mandatory for Building Regulations in the UK?

Fire-rated cavity closers are required in specific situations under Part B of the Building Regulations. However, not all cavity closers are fire-rated because their requirement varies depending on the building’s use and specific areas within it.

Fire-rated cavity closers are typically required in critical zones like escape routes, stairwells and areas with high fire risk. In other parts of buildings, where fire risk is lower or compartmentalisation is less critical, non-fire-rated cavity closers can effectively maintain thermal efficiency and moisture control. These non-fire-rated alternatives offer a cost-effective solution without the added expense and complexity associated with fire-rated materials.

To ensure compliance with local building codes, it’s important to assess the fire safety requirements of your building project and consult with building professionals or regulatory authorities to determine where fire-rated cavity closers are necessary.

Where can I find installation guides for your insulation cavity closers products?

Proper installation of insulation cavity closers is crucial for optimal performance. At Subframes, we provide comprehensive installation guides with each product to assist you. These guides include step-by-step instructions to ensure your cavity closers are installed correctly. For quotations, product information or technical support please call us on 01773 590100 or email [email protected]

Can I find links to your customer reviews?

Yes, you can find links here: Read our Google reviews!

Are cavity closers considered insulation?

Yes, cavity closers serve as insulation by sealing gaps around window and door openings in cavity walls. They prevent heat loss and protect against moisture ingress. For more details, you can visit our Insulation Products Page and explore the various options available. Additionally, our Installation Guides provide links to detailed instructions on how to install cavity closers effectively.

Quick Enquiry